This article examines how IoT technologies can significantly reduce bottlenecks in the supply chain. By using the IoT , operational efficiency and customer satisfaction are improved in various industries. We aim to provide a comprehensive understanding of the transformative impact of IoT on supply chain management by highlighting real-world applications and benefits.

Introduction: What is a supply chain bottleneck?

Global supply chains face a variety of challenges, which are exacerbated by the increasing complexity and interconnectedness of the global economy. Unpredictable changes in demand, logistical problems, geopolitical tensions and a lack of transparency along the supply chain are current problems that affect efficiency and reliability and lead to bottlenecks.

A supply chain bottleneck occurs when one or more links in the chain cannot fulfill their function properly, causing the entire process to be delayed or interrupted. This can be caused by production delays, transportation problems or a shortage of raw materials.

These challenges can be significantly reduced by the Internet of Things (IoT). IoT is a network of physical objects equipped with sensors, software and other technologies to collect and exchange data. In supply chain management, IoT offers better monitoring and control of various processes and components, resulting in greater transparency and optimized workflows. Ultimately, bottlenecks can be reduced.

What leads to a bottleneck in supply chain management

A bottleneck in supply chain management can be caused by a variety of factors. We look at common causes in this section.

Inefficient inventory management

Poor inventory management can lead to companies having either too much or too little stock. Overstocking ties up capital and increases inventory costs, while missing key materials or products can halt production and cause delivery delays. Inefficient inventory management is often the result of a lack of real-time monitoring and inadequate stock control.

Poor demand forecast

Inaccurate forecasting of demand can lead to companies being unable to react appropriately to market fluctuations. This results in over- or underproduction and is exacerbated by inadequate data analysis or a lack of advanced forecasting tools.

Insufficient transparency throughout the supply chain

A lack of transparency means that problems such as delays, quality defects or transportation problems cannot be identified and rectified in good time without real-time insight into the various stages of the supply chain.

Dependence on manual processes

Manual processes are error-prone and time-consuming. Dependence on such processes often leads to significant delays and inaccuracies. Automation and digital technologies are often lacking in traditional supply chains, which impairs responsiveness and efficiency.

Effects of bottlenecks on company efficiency and customer satisfaction

Bottlenecks can lead to production delays and business interruptions, resulting in a reduction in production capacity and an increase in operating costs. Downtime occurs when required materials or products are not available on time. Customers expect flawless products to be delivered on time. Dissatisfied customers lose confidence in the company, which has a negative impact on its image and customer loyalty.

Overview of the integration of IoT into supply chain systems

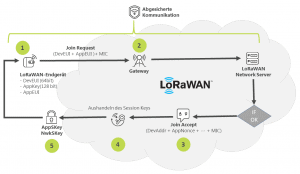

IoT-RFID technologies enable physical objects and digital systems to network and communicate with each other along the entire supply chain. Sensors, RFID tags and other network devices can be used at various points in the supply chain to capture and transmit important data in real time. This continuous data transmission provides comprehensive transparency and enables extensive control.

Advantages of using IoT for real-time data collection and analysis

Real-time visibility enables quick responses to problems and improves demand management, avoiding bottlenecks and overstocking. Proactive maintenance of assets is also possible. The optimization of route planning is also a decisive advantage.

How IoT can eliminate bottlenecks in the supply chain:

1. automation and efficiency: IoT solutions enable the automation and optimization of many manual processes in the supply chain. Automated inventories using IoT sensors replace manual counting, saving time and increasing accuracy. IoT-Sensors monitor the condition of machines and proactively report maintenance needs. IoT-Devices can also optimize transport routes based on real-time traffic data.

2. real-time inventory tracking and management: IoT devices ensure continuous, real-time inventory monitoring. Real-time data enables timely replenishment planning and optimal inventory management, minimizing the risk of supply shortages or overstocking.

3. improved demand forecasting: By using IoT-generated data, the accuracy of customer demand forecasting is significantly improved. Companies can make more accurate predictions by analyzing real-time data on sales figures, market trends and consumer behavior.

4. increased transparency in the supply chain: networked sensors and devices provide data on the condition and location of goods throughout the transportation and production process. This transparency enables companies to identify problems at an early stage and take immediate action.

Summary: Global bottlenecks in the supply chain

This article has discussed the main causes of bottlenecks in the global supply chain and their negative impact. The most common causes include inefficient inventory management, poor demand forecasting, insufficient visibility and reliance on manual processes. IoT has transformative potential to address these challenges. IoT-Among other things, devices can check stock levels in real time, optimize demand forecasts and increase transparency throughout the supply chain. All of this leads to increased efficiency and reduced bottlenecks. Business decision makers should consider IoT solutions to realize the full potential of the supply chain and remain competitive. Now is the time to rethink!