Missing parts, critical tools or unfinished products on the production line often lead to expensive delays, costly downtime and stalled production. Non-transparent, inefficient material flows within the plant also slow down productivity and make it difficult to meet tight schedules.

A lack of transparency about the exact location and condition of important supplier parts in transit to the plant causes unpredictable delays that are difficult to calculate. This leads to losses, inefficient scheduling and jeopardizes the ability to plan and the reliability of the entire supply chain and production.

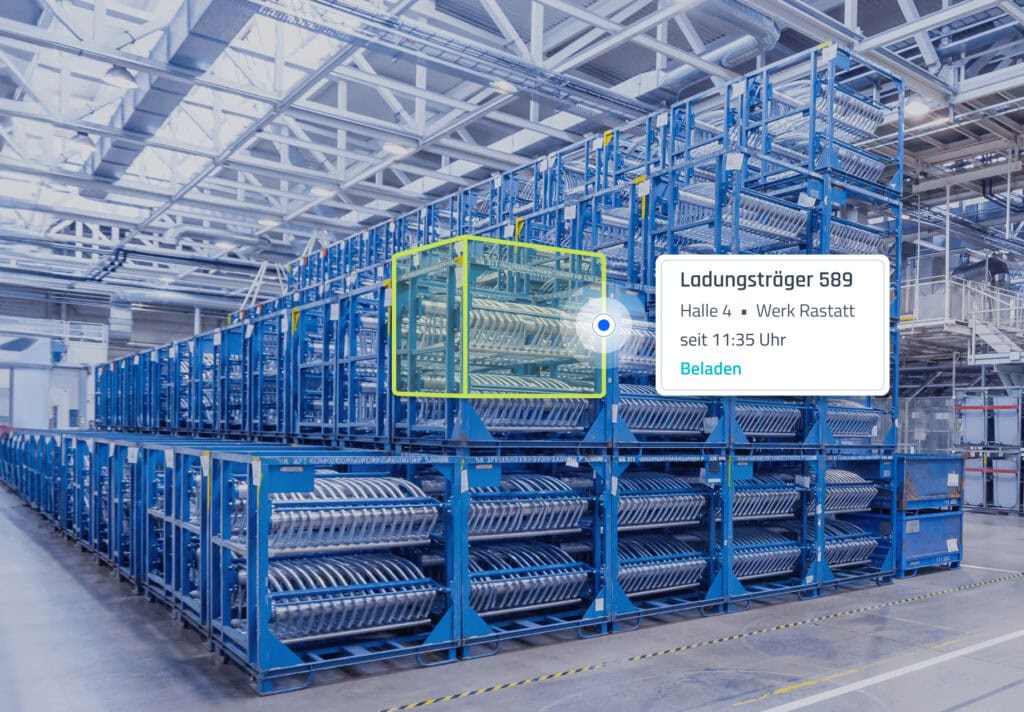

The continuous loss and inefficient, slow circulation of expensive reusable transport containers not only cause high replacement costs and tie up capital unnecessarily. In fact, missing load carriers also jeopardize the smooth supply of parts and can result in serious production bottlenecks or even stoppages.

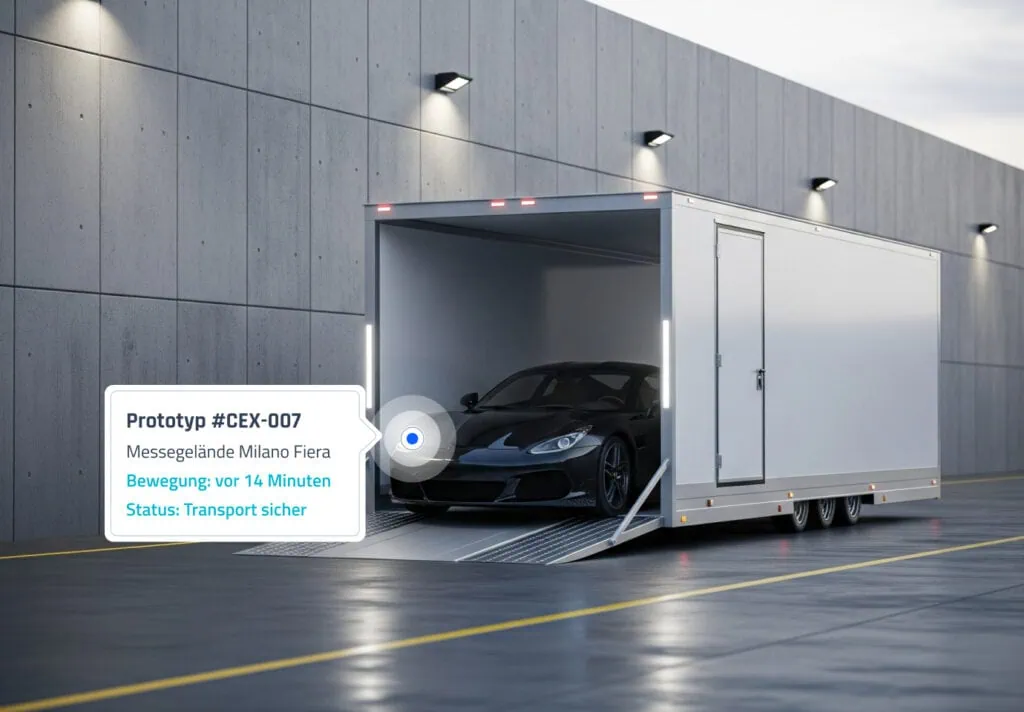

The loss, damage or unauthorized access to highly sensitive, often irreplaceable prototypes during transport and use at external events and customer roadshows represent an enormous financial, competitive and reputational risk. A lack of real-time control and complex logistics significantly increase the risk.

The gradual loss of high-quality, mobile tools, their low utilization due to frequent untraceability and uncontrolled, unregistered operating resources lead to significantly high costs. This often results in noticeable production delays and poses risks due to missed, safety-relevant maintenance or calibration intervals.

Your advantages:

Arrange a personal consultation with our experts. We will be happy to analyze your problem together with you and advise you on possible solutions and potential.

© 2024 SmartMakers GmbH - All rights reserved - Imprint - Privacy Policy