IOT ASSET TRACKING

Improve and automate business processes by localizing all assets

What is IoT Asset Tracking?

Connect your assets via the thingsHub tracking platform and modern IoT asset trackers for more transparency in all processes.

Capture all important movement data with asset trackers that are easy and cost-effective to install. With just one click you know the location, condition and status of your load carriers, pallets, tools, vehicles or equipment. Receive automatic alarms and warnings, e.g. when leaving or reaching defined zones,even in factory buildings and on construction sites.

Areas of application

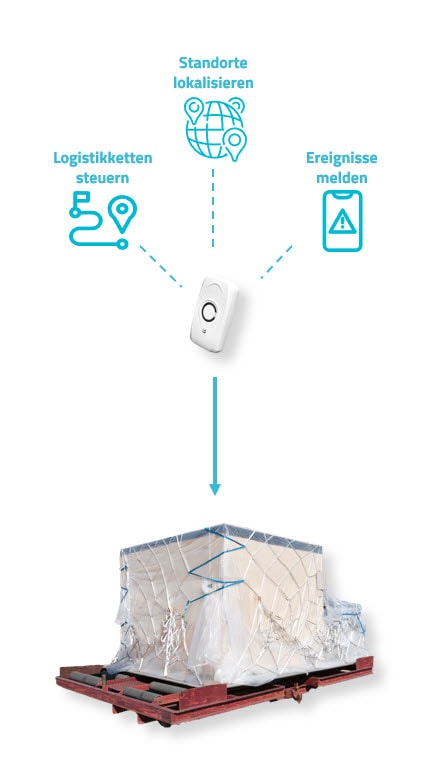

Track transports and shipments

Time and again, goods are lost on the delivery route, are stolen, spoil due to an interruption in the cold chain or are damaged by shocks. If these problems are detected too late, the delivery date can usually no longer be met. IoT makes the supply chain transparent. Intelligent trackers send their data in real time along the entire delivery route.

Faster and transparent customer delivery

Accelerate processes and increase quality

Permanently reduce running costs

Faster and transparent customer delivery

Accelerate processes and increase quality

Permanently reduce running costs

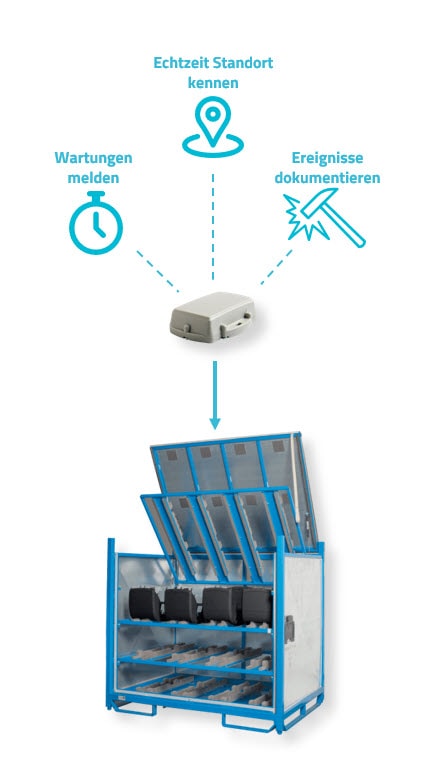

Monitor and control load carriers

Localise the load carriers in real time and know how many are at which production sites and in which intralogistical processes. IoT makes each load carrier uniquely identifiable and gives it its own status. Transparency beyond the interfaces supports optimisation.

Prevent shrinkage

Accelerate return to the pool system

Avoid expensive investments

Prevent shrinkage

Accelerate return to the pool system

Avoid expensive investments

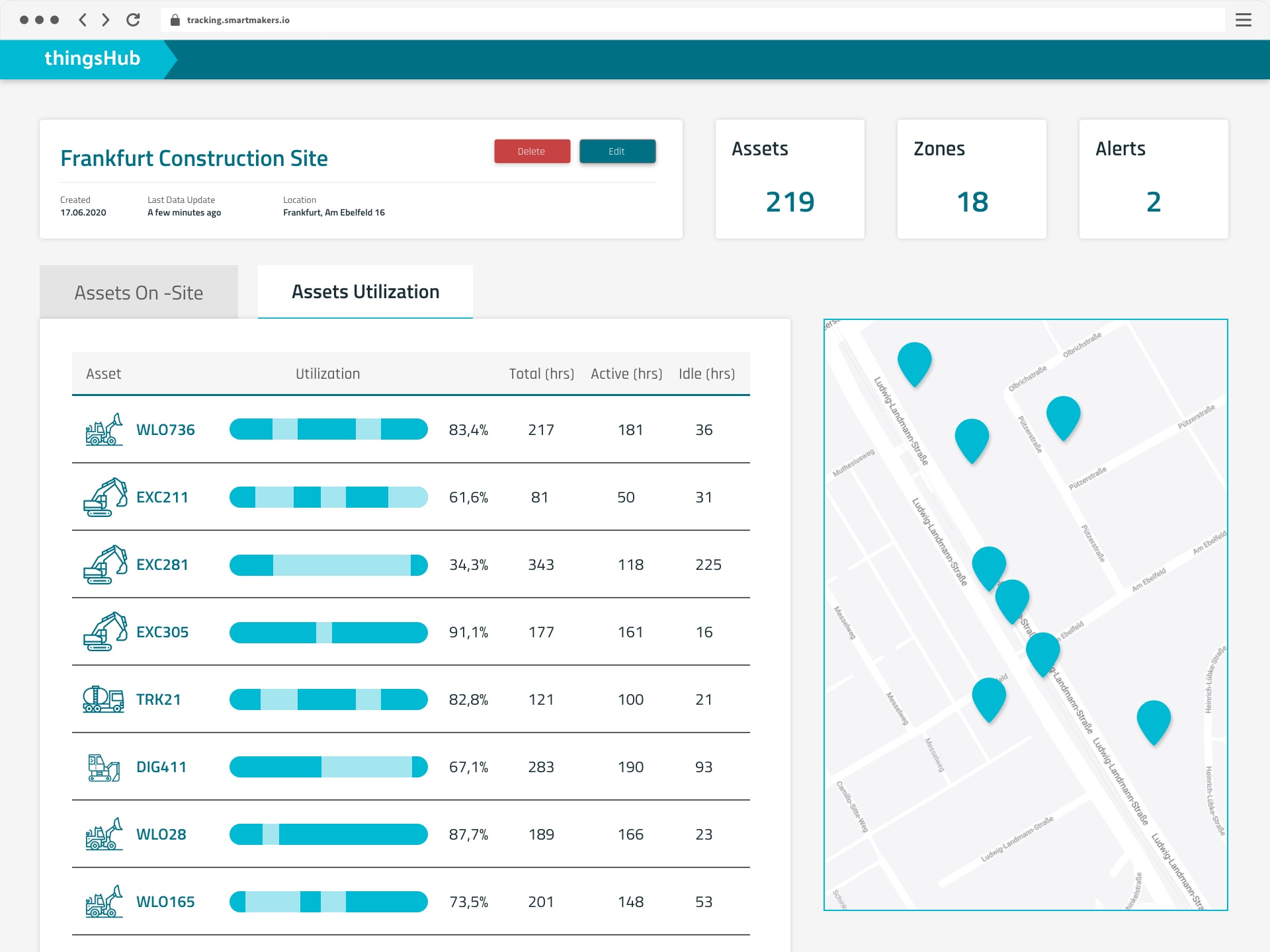

Monitor construction machinery and tools

Intelligent tracking ensures more productivity and transparency. Because IoT makes it easy to find and track devices, machines, tools and equipment, as well as to optimise scheduling and targeted deployment of staff and resources while avoiding bottlenecks.

Improve utilisation and availability

Prevent theft

Minimise maintenance, repair and new acquisition costs

Improve utilisation and availability

Prevent theft

Minimise maintenance, repair and new acquisition costs

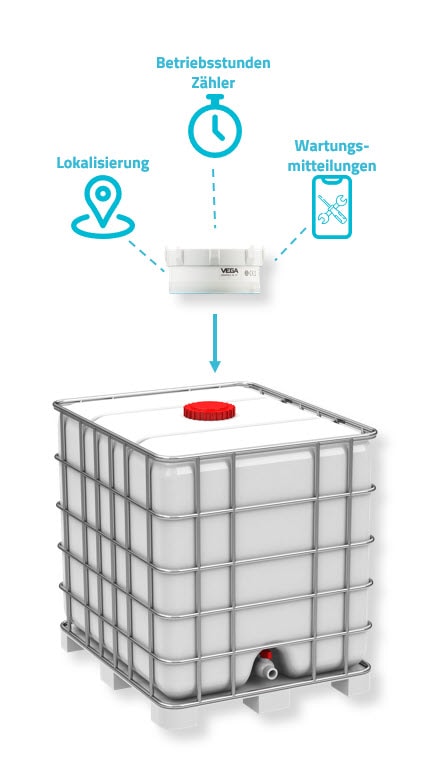

Monitor containers and IBC containers

See exactly where bins are, how much they are full and which ones need to be reconditioned or serviced. Get 24/7 visibility over bin data for predictive maintenance and route planning, usage-based billing and new customer services. Increase inventory management efficiency with IoT technology.

Avoid buffer stocks

Monitor usage history

Increased efficiency for drivers and customers

Increase your delivery margins

Avoid buffer stocks

Monitor usage history

Increased efficiency for drivers and customers

Increase your delivery margins

Optimize pool and reusable transport systems.

Reusable transport systems such as containers, crates and load carriers are used in production logistics and goods handling, among other things. With intelligent IoT sensor technology, it is possible to reduce their number in the cycle and optimise throughput times at the same time. Disruptions in the supply chain are reduced.

Increase service level

Reduce stocks

Eliminate shrinkage risk

Automate rental fee accounting

Increase service level

Reduce stocks

Eliminate shrinkage risk

Automate rental fee accounting

Find vehicles faster and manage them better

By using smart IoT trackers in vehicles, any vehicle can be found at any time anywhere on the premises and in buildings within a few minutes without any installation effort. With reliable and secure data, efficiency increases in business processes are possible.

Reduce search times

Optimise throughput times

In workshop buildings & showrooms

Maintenance free for several years

Reduce search times

Optimise throughput times

In workshop buildings & showrooms

Maintenance free for several years

thingsHub EveryWHERE

Asset localisation

Features of

thingsHub Asset Tracking

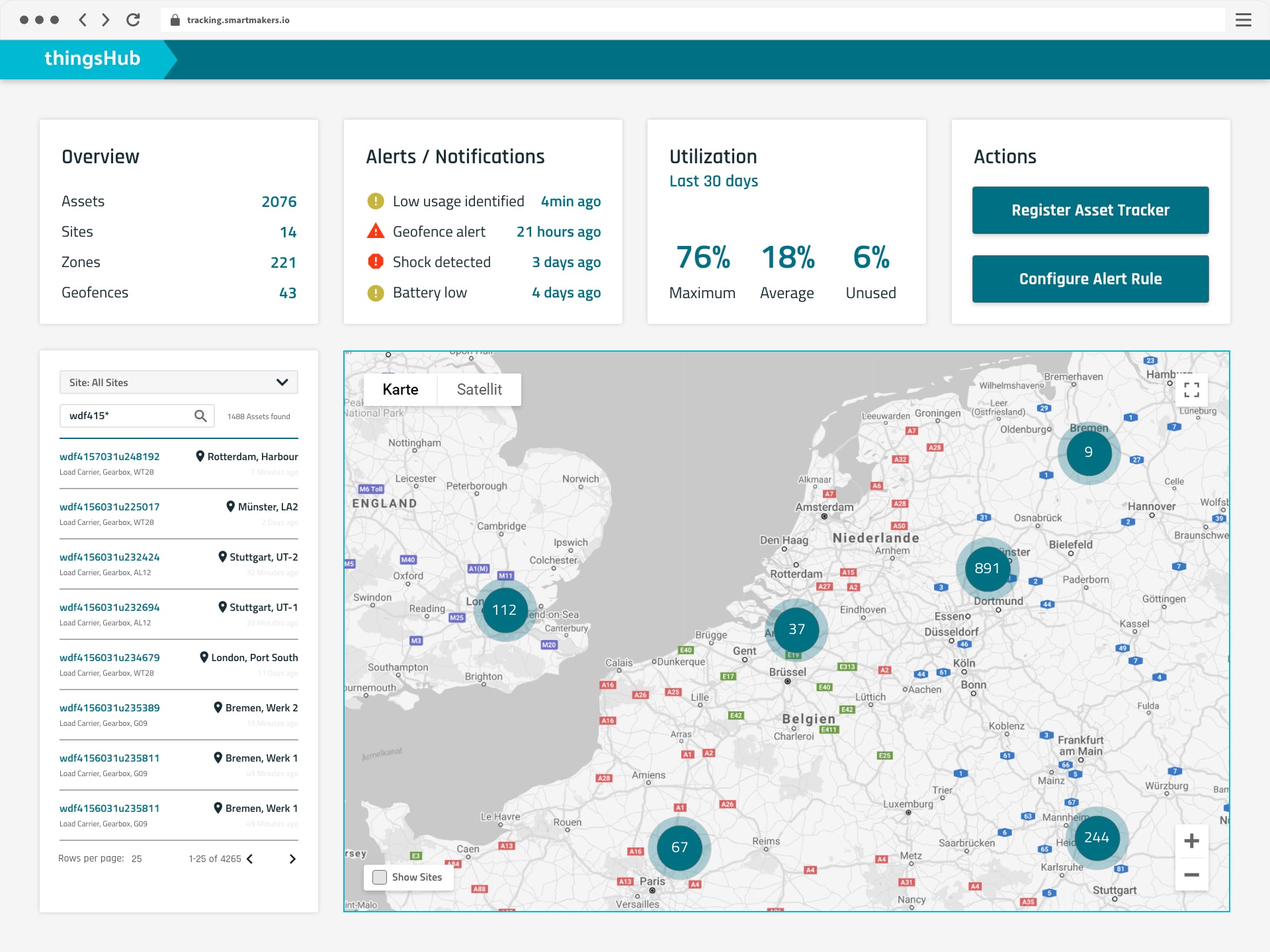

Everything in view with one click

With the modern web interface of thingsHub Tracking you always keep track of all assets from your area of responsibility. On your workstation, tablet or via mobile phone.

- Locating your assets indoors and outdoors (indoor and outdoor location)

- Low power asset tracker with battery life of up to 10 years

- Geographical full text search to find resources quickly and reliably

- Detection of problems and anomalies according to a freely definable set of rules

- Recognize and react to quality problems at an early stage

- Automatic acquisition of condition values over long periods of time.

- No more manual effort required

- Demonstrate compliance to customers and regulators

- Direct notification in the event of non-compliance

Know the condition of goods and merchandise at all times

With condition monitoring, you can monitor and document the condition of your equipment and goods anytime and anywhere. Whether they are being transported, are at your supplier's or arrive at the goods receiving department. You know all the important condition values such as temperature, humidity or whether there have been strong impacts during transport.

- Recognize and react to quality problems at an early stage

- Automatic recording of condition values over long periods of time. Reduce manual efforts

- Demonstrate compliance to customers and regulators

- Direct notification in the event of non-compliance

- Recognize and react to quality problems at an early stage

- Automatic acquisition of condition values over long periods of time.

- No more manual effort required

- Demonstrate compliance to customers and regulators

- Direct notification in the event of non-compliance

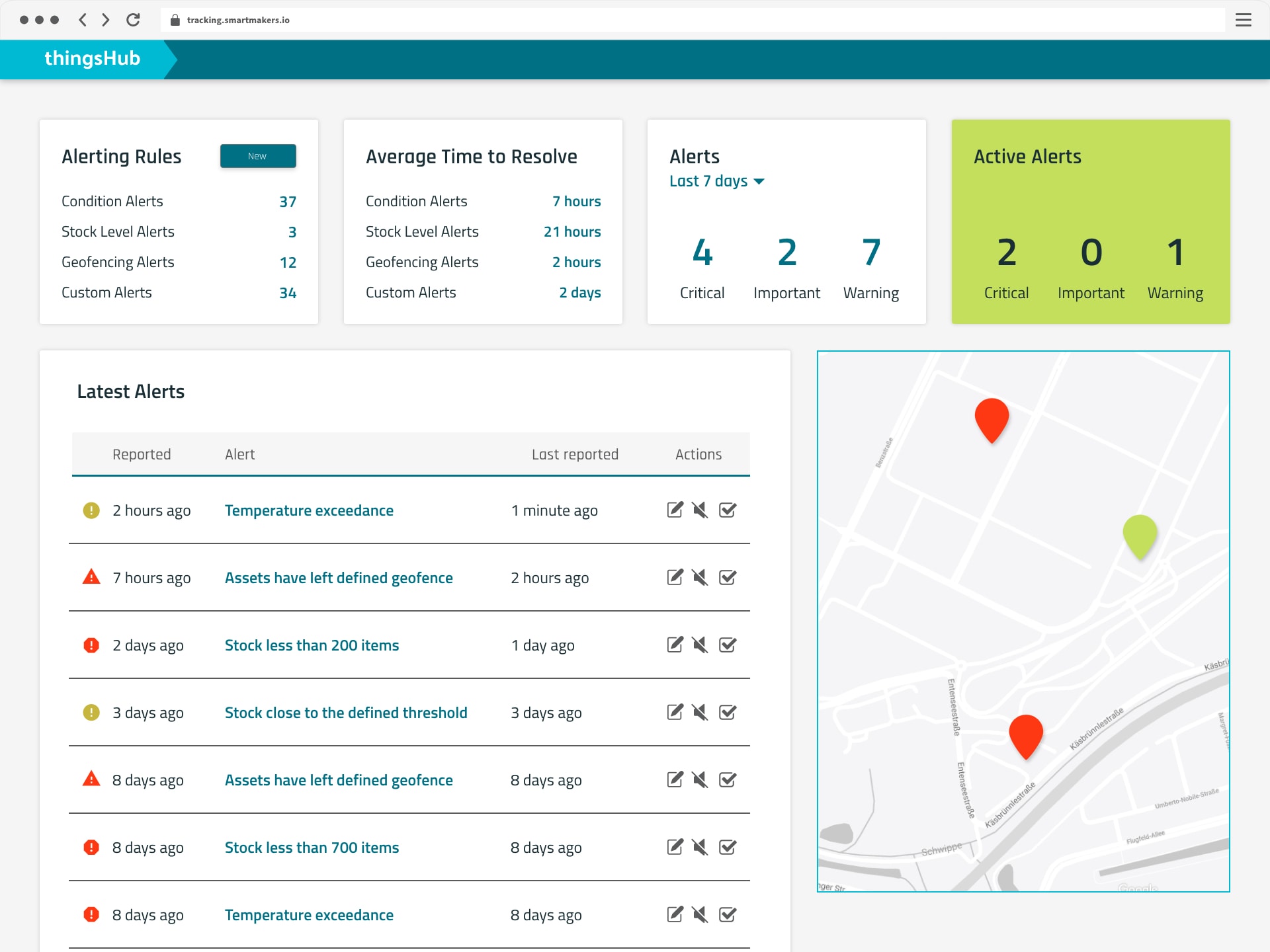

Recognize problems in order to be able to react earlier

Create your own rules and alerts according to which thingsHub Tracking monitors your assets. If there is a problem, the system will notify you via SMS, email or any other digital channel of your choice. With just a few clicks, create custom areas on your digital map that your assets are not allowed to leave or where definable actions should occur.

- Set up your own alarm rules and be notified of problems via SMS, email and other digital channels.

- Cockpit overview of all active and past messages

- Delegate problems directly to teams and individuals who can solve the problem most quickly

- Identify recurring problems in workflows and processes

- Recognize and react to quality problems at an early stage

- Automatic acquisition of condition values over long periods of time.

- No more manual effort required

- Demonstrate compliance to customers and regulators

- Direct notification in the event of non-compliance

Understand how extensively resources are used

There is often a lack of real data and a constantly updated overview to determine the deployment and utilization of operational centers such as load carriers, construction vehicles and equipment. ThingsHub Tracking provides you with this data and enables you to make better data-driven decisions.

- Know the degree of utilization of load carriers, vehicles and equipment

- Understand how long assets stay in defined geo-zones and if there are too many load carriers

- Be notified if stock levels are too low or too high

- Recognize and react to quality problems at an early stage

- Automatic acquisition of condition values over long periods of time.

- No more manual effort required

- Demonstrate compliance to customers and regulators

- Direct notification in the event of non-compliance

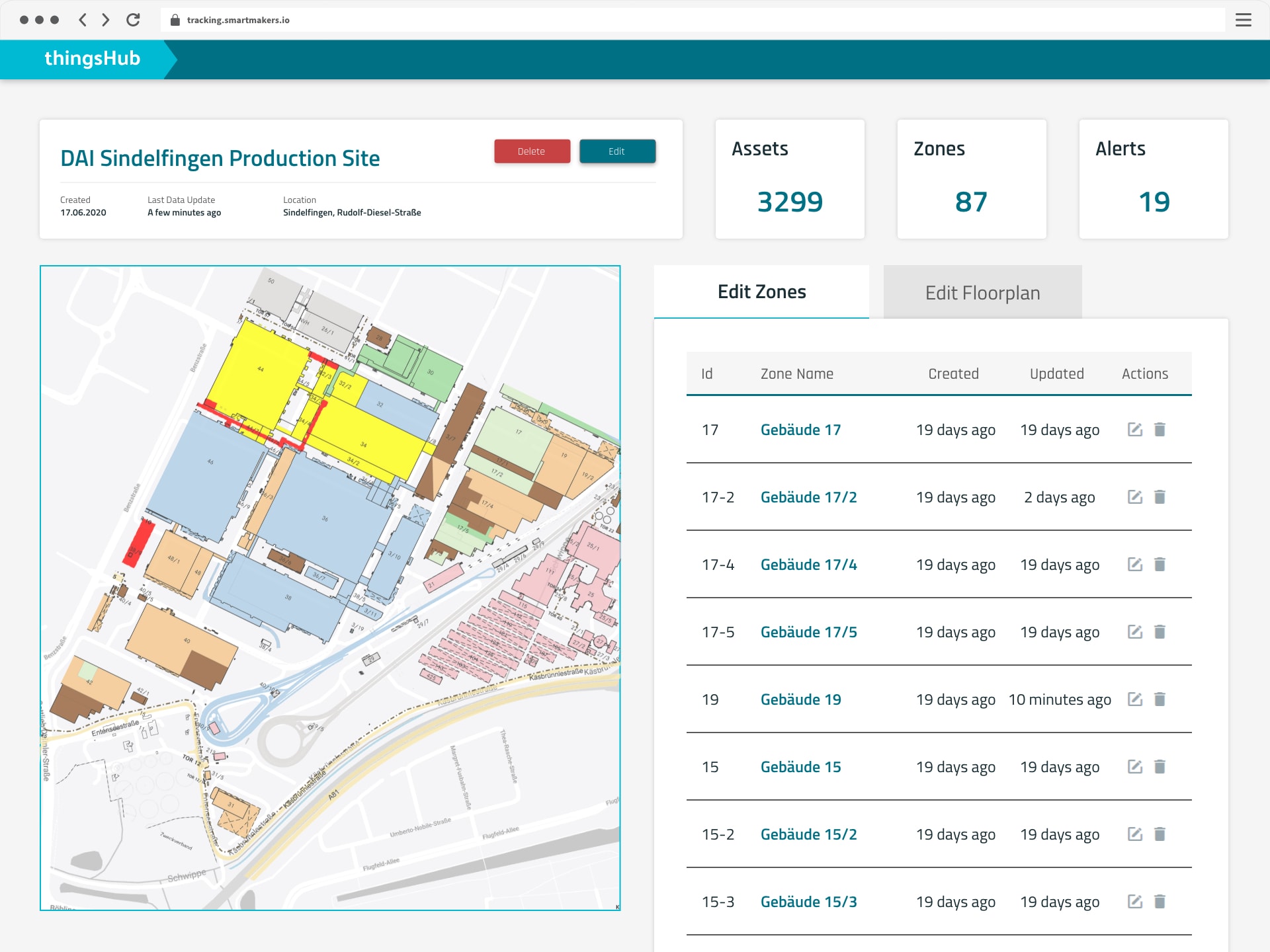

Digital Twin Maps: Map business processes with your own maps

It's a bit like hiking. Without a good map with lots of information, you can't navigate even with the best GPS location. For this reason, you can add your own maps and information about your locations to the digital maps in thingsHub Tracking. So that in the end your load carrier shows the location "Factory Hall 4.1" and not only Munich South.

- Add your own site plans and floor plans to digital maps

- Define new zones and geo-fences for own, supplier or customer locations with just a few mouse clicks

- Filter by locations and zones to find resources faster

- Recognize and react to quality problems at an early stage

- Automatic acquisition of condition values over long periods of time.

- No more manual effort required

- Demonstrate compliance to customers and regulators

- Direct notification in the event of non-compliance

References

EIFFAGE Construction

CONSTRUCTION FRAMEWORK

Savings of 35% by optimizing the utilization of construction site assets

Car dealer group Spindler

AUTOHUSER

Turnaround time reduction of 25% through automated localization of vehicles on the premises.

SUSS MicroTec

FINISHING

53% reduction of search, bookkeeping and inventory efforts for internal transport containers

Deepen your knowledge of Asset Tracking

whitepaper

The top 9 savings potentials with IoT

webinar

Tracking of reusable transport containers

How can we

help you?

Arrange a personal consultation appointment with our experts. We will be happy to advise you on your personal area of application.

2023 © SmartMakers GmbH - All rights reserved - Imprint - Privacy Policy