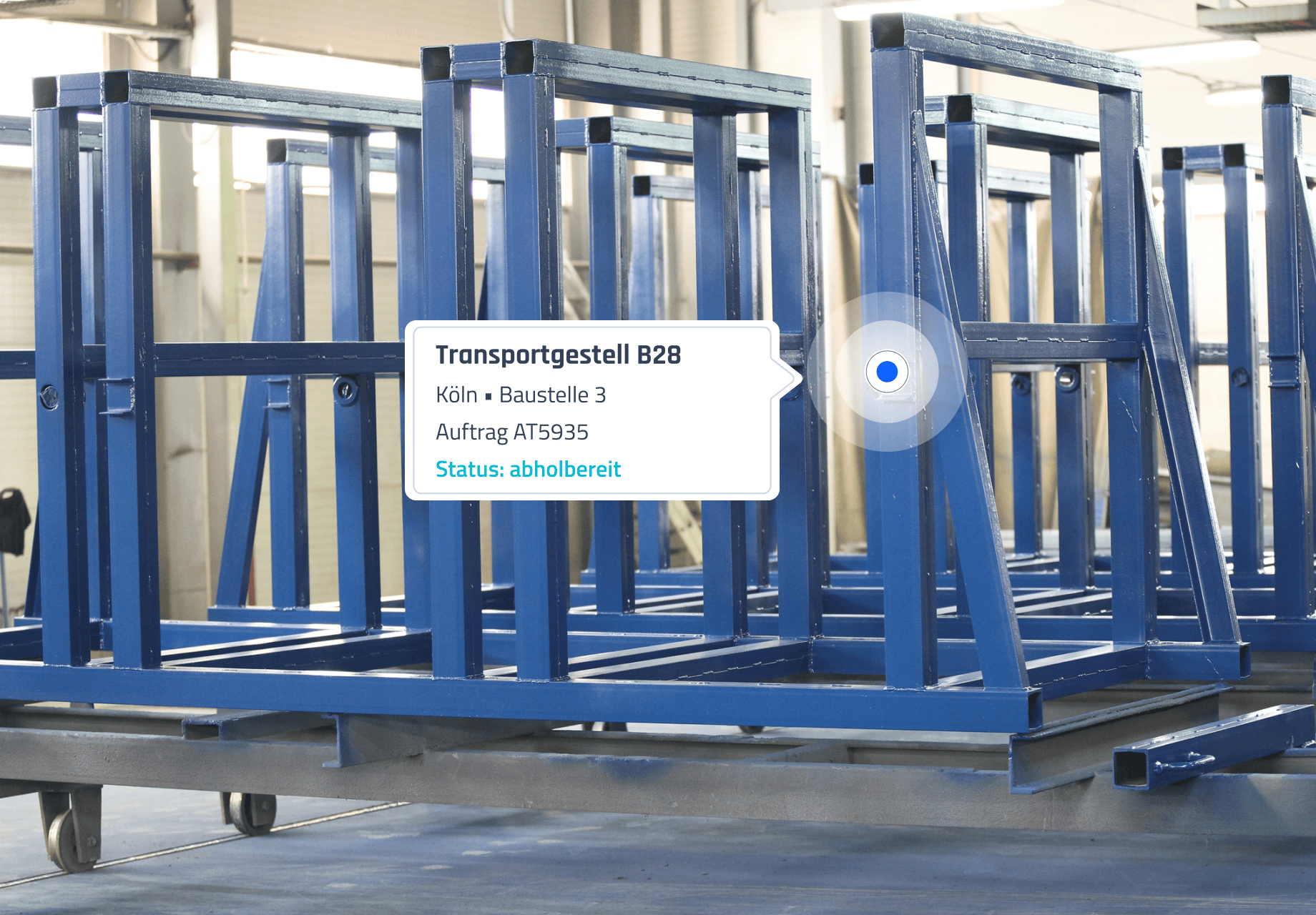

There is no precise overview of the location and status of your transport racks. The lack of an inventory overview leads to bottlenecks that disrupt the production process. In addition, your racks are often misused by customers due to their wide range of applications. To compensate for shrinkage and avoid bottlenecks, you need to purchase additional racks and maintain buffer stocks.

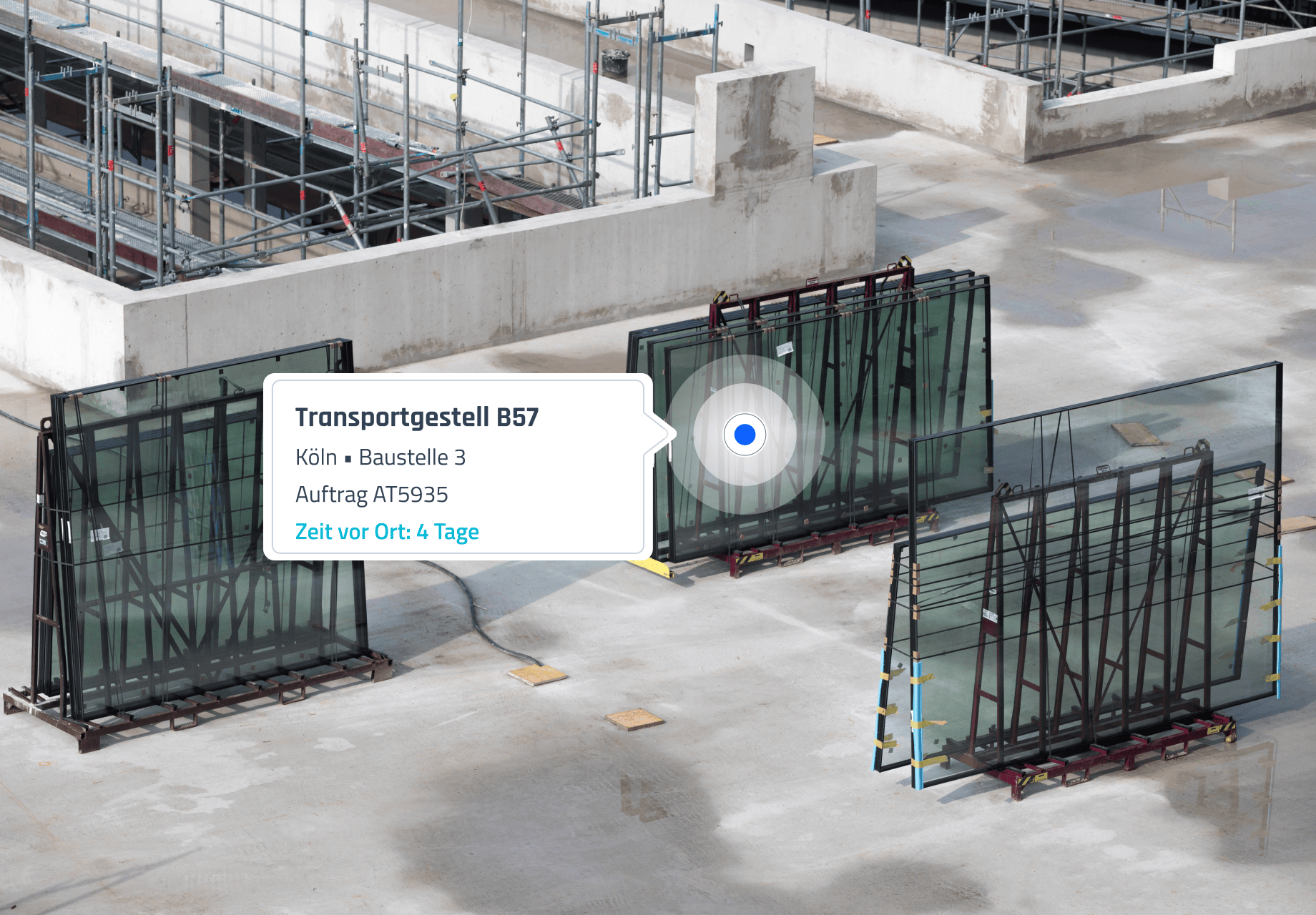

The release of your racks is unreliable and delays collection. Empty racks are not returned on time, which leads to additional logistical costs and, in the worst case, delays in production. Empty racks are in the way on construction sites and have to be relocated, causing dissatisfaction among your customers on site.

The shortage of skilled workers in technical professions makes it difficult for you to find qualified employees for production and product development. A lack of capacity slows down your operational processes. This often leads to a higher workload for existing staff and increases the risk of errors or delays. At the same time, production processes need to become increasingly flexible, leading to a greater need for automation.

Space and storage options are often limited on construction sites. A premature delivery of construction elements can hinder work on the construction site, while a late delivery delays the entire construction process. Waiting or downtime can result in high costs. You therefore need to coordinate your deliveries precisely with the construction progress, which is difficult to coordinate manually.

After the webinar you will know how to ...

Arrange a personal consultation with our experts. We will be happy to analyze your problem together with you and advise you on possible solutions and potential.

© 2024 SmartMakers GmbH - All rights reserved - Imprint - Privacy Policy