Paperless manufacturing is quickly gaining popularity and becoming a major trend in the manufacturing industry as we move into the age of digitalization. This strategy uses electronic alternatives to traditional paper-based technologies to simplify and improve the production process. The adoption of paperless manufacturing has demonstrated many benefits for companies, including lower costs, increased production efficiency, higher quality control and reduced environmental impact.

Implementing a paperless manufacturing system can be difficult, especially for companies that have long relied on paper-based methods. However, with the right preparation and guidance, the transition to a paperless system can be effective and smooth. This article aims to provide advice on how to successfully implement paperless manufacturing, including the necessary tools and best practices.

Advantages of paperless manufacturing

Lower operating costs

By eliminating paper, companies can reduce their paper, printing, storage and distribution costs. This can result in significant cost savings for the company. Paperless production can also reduce the cost of disposing of paper waste. In addition, paperless production enables savings in labor costs by eliminating the manual handling of paper, thereby freeing up employee capacity. This means that employees can work more effectively and productively, saving the cost of manual paper processing.

Higher efficiency and productivity

Paperless manufacturing enables real-time data collection, analysis and reporting, leading to better decision making and faster response times. Through the use of IoT sensors, data can be collected and analyzed directly from the production floor, allowing for faster response when deviations from target values occur. Electronic work instructions and digital drawings can also speed up production and reduce errors. In addition, the use of augmented reality can simplify and speed up complex work processes. Furthermore, digital documentation can contribute to improved communication between departments and employees, as information is centrally accessible and easier to share.

Improved quality control

With paperless manufacturing, companies can build a closed-loop quality system that enables real-time tracking and monitoring of quality data. By using IoT sensors, relevant data such as temperature, pressure or humidity can be directly captured and monitored in real time. As a result, quality problems can be quickly identified and remedied even before they lead to major damage. Digital documentation enables complete traceability of all process steps and thus facilitates the identification of the causes of quality problems. Improved quality control can increase product quality, which leads to higher customer satisfaction and improves the company's image.

Lower environmental impact

By eliminating paper waste, companies can significantly reduce their environmental footprint and contribute to sustainability. Paperless manufacturing also reduces physical space requirements, which can lead to lower energy needs for lighting and air conditioning. Going paperless and using digital documents can also reduce CO2 emissions generated by paper manufacturing and the transportation of paper products. In addition, the use of IoT sensors can also save resources such as electricity and water by, for example, only running machines when they are actually needed. Paperless production can thus make an important contribution to environmental protection and sustainability.

Can you also use these advantages for your challenge? Talk to us and together we will find the way to paperless manufacturing in your company.

Implementation of paperless manufacturing

5 steps to implementing paperless manufacturing

- Conduct a feasibility study and evaluate the potential benefits and risks of implementing paperless manufacturing.

Before implementing paperless manufacturing, it is important to conduct a feasibility study. This study helps to evaluate the potential benefits and risks of paperless manufacturing. It involves analyzing the processes to be digitized and assessing the potential impact on the organization and employees.

- Create a detailed plan and schedule for the implementation process.

A detailed plan and schedule is required to ensure successful implementation of paperless manufacturing. The plan should include all the steps and actions required for implementation, including the resources needed and the responsibilities of the people involved.

- Identifying and prioritizing processes and areas for digitization.

Identifying and prioritizing processes and areas for digitization is an important step in implementing paperless manufacturing. It is important to identify the processes that will benefit most from digitization to ensure that the system brings the greatest possible benefit to the company.

- Set up a pilot project to test the system and make necessary adjustments.

Before implementing the system throughout the company, it is useful to set up a pilot project to test the system and make necessary adjustments. The pilot project enables potential problems to be identified and resolved before the system is implemented throughout the company.

- Roll out the system throughout the company

Once the pilot project has been successfully completed, the system can be rolled out throughout the company. It is important that all employees are informed and trained about the benefits of the system to ensure that they can use it effectively.

Tools and technologies for paperless manufacturing

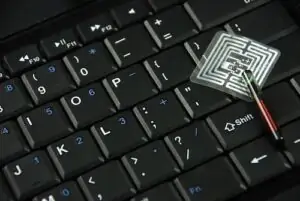

IoT devices: TheInternet of Things (IoT) is an important component of paperless manufacturing. Sensors and machine controls can be used to collect and monitor data in real time. This can help increase production efficiency and productivity by quickly identifying and resolving any bottlenecks.

Electronic work instructions and digital drawings: An important prerequisite for paperless manufacturing is the use of electronic documents such as work instructions and drawings. These can be easily edited and updated, resulting in improved accuracy and consistency of information. Using digital documents can also save time and money on printing and distributing paper documents.

Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems: The use of MES and ERP systems is another important component of paperless manufacturing. These systems can be used to collect, analyze and manage data, which can lead to improved decision making and higher performance of production processes.

Cloud-based storage and collaboration tools: Using cloud-based storage and collaboration tools allows employees to access documents and data anytime, anywhere. This can improve collaboration between teams and departments and help increase production efficiency and productivity. Cloud-based systems also provide a secure and scalable way to store and back up data.

Best practices for successful implementation of paperless manufacturing

Employee training and involvement: Successful implementation of paperless manufacturing depends on employee acceptance and support. Training and workshops help improve understanding of the new system and promote employee motivation and readiness. It is important to communicate the benefits and positive effects of the new technology to promote a positive attitude.

Establish standardized procedures and workflows: By standardizing procedures and workflows, errors and inconsistencies can be avoided. It is important to define clear instructions and processes to ensure that all employees use the same way of working.

Regular maintenance and updates of software and equipment: Paperless manufacturing requires regular maintenance and monitoring to ensure smooth operations. It is important to ensure that all systems and equipment are up to date and performance is optimized.

Continuous improvement and monitoring: The implementation of paperless production is a continuous process. Further optimization potential can be identified and exploited through continuous monitoring and improvement. By analyzing data and feedback, improvements can be made to further increase efficiency and productivity.

Why should anyone choose paperless manufacturing and logistics today?

Implementing paperless manufacturing offers companies numerous benefits, including lower operating costs, increased efficiency and productivity, improved quality control, and a reduced environmental footprint.

To successfully implement paperless manufacturing, companies should conduct a feasibility study; create a detailed implementation plan; leverage tools and technologies such as IoT devices, MES and ERP systems, and cloud-based storage and collaboration tools; and implement best practices such as employee training and engagement, standardization of procedures and workflows, regular maintenance and updates to software and equipment, and continuous improvement and monitoring.

Given the increasing importance of sustainability, digitalization and efficiency in the manufacturing industry, paperless manufacturing is a forward-looking investment for companies. By switching to paperless manufacturing, companies can not only reduce their costs and improve their processes, but also contribute to environmental protection and strengthen their competitiveness in the market.

Would you now also like to switch to paperless manufacturing? How? We'll show you.