2024-04-17 | Press release

SmartMakers supports DAAD project of Neu-Ulm University of Applied Sciences and the University of Western Cape with tracking solution

Many companies have aligned their business models in such a way that they benefit from global supply chains. For most, these have even become indispensable - whether as a cost-effective alternative to local production or in order to be able to access certain resources or raw materials at all.

As part of the DAAD project GIPS4VC, Neu-Ulm University of Applied Sciences (HNU) has set up a global supply chain together with its partner university, the University of the Western Cape (UWC). As a tracking technology supplier, SmartMakers GmbH is supporting the project to ensure transparency in the production and supply chain.

Project objective: Establishment of a global supply chain

The idea of the DAAD project Global Production and Supply Chain Network for Virtual Collaboration (GIPS4VC) was to create a real global supply network between the UWC and the HNU. They were to work together as supplier and manufacturer for project-based virtual learning blended mobility format. The 57 students from both universities were to gain real-life experience in interdisciplinary, international and intercultural teamwork during a project week from 14 to 21 May 2023 in Cape Town.

During the project week, the students planned to use the Flytech Ltd. production site in Cape Town as a supplier for Drohnen GmbH in Leipheim. They established information and material flows for the production of the flight controller, an important drone component.

The tasks included setting up a data transfer system using a cloud solution for customer orders, delivery bills and status reports as well as automated order processing using robotic process automation.

Another goal was to build a global value-added network and monitor the transportation of products using a tracker. The students were able to gain the company SmartMakers as a partner for this.

SmartMakers delivers tracking technology

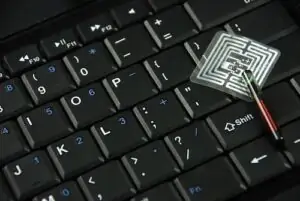

As part of the project, SmartMakers GmbH acted as a provider of tracking technology. Using a flight tracker and the thingsHub platform, the project team monitored the transport and thus the current status, including the calculation of the expected arrival of the shipment.

For Drohnen GmbH Leipheim, this opens up completely new possibilities for production planning. Thanks to transparent shipment tracking, it is always clear where the materials required for the flight controller are located and when they are expected to arrive.

This real-time visibility brings enormous benefits for companies, particularly in the supply chain. In addition to improved supply chain planning, real-time monitoring leads to an increase in efficiency, enables faster response times and creates better collaboration between suppliers and their customers.