How production companies benefit from an RTLS

Every day, production companies face the challenge of continuously optimizing their processes, ensuring smooth material flows and staying ahead of the competition. Real-time location systems (RTLS) offer valuable support here by enabling the tracking of materials, loading equipment, tools and products in real time.

An RTLS thus creates transparency along the entire value chain and allows for more precise planning and control of production processes, control of stock levels and the ability to use production facilities more efficiently. This leads to significant cost savings by reducing search times, shortening throughput times and optimizing stock levels.

Especially in times of a shortage of skilled workers, the digitalization and automation of processes allows employees to work productively. They are no longer occupied with search efforts and time-consuming manual activities.

An additional advantage is the ability to identify valuable optimization opportunities through data-supported process analyses. This enables companies to make continuous improvements to their production processes based on the real-time data collected and proactively avoid bottlenecks, production disruptions and delivery delays. An RTLS can therefore be a decisive competitive advantage for production companies.

What is an RTLS and how does it work?

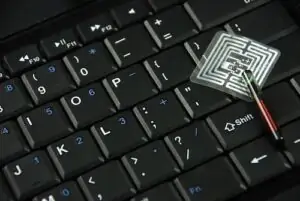

A real-time location system is a highly precise and versatile system for determining and tracking the position of objects or people in real time. It is based on the localization of devices that emit signals using Bluetooth, ultra-wideband or other technologies. For this purpose, tags are attached to the assets to be tracked, which calculate their position via a network of anchors. The position data can be determined through clever interaction between the components:

- A tracking tag sends signals at regular intervals. These are received by all anchors in the communication area and sent to the central system with a time stamp. It calculates the coordinates of the tag from the differences in the arrival times at the individual anchors.

- Alternatively, RTLS sensors can detect the received signal strength to determine the location of the transmitting devices.

- At the same time, they can also measure the angles of signals emitted by the tags. This information enables the location to be determined with a high degree of accuracy.

- But the tags can not only send signals to the anchors, they can also communicate directly with each other. When one device is in close proximity to another, they begin to detect each other in order to determine their distance.

The collected signal data is processed in a central software and the exact position of the tags is calculated. These are displayed in a user-friendly interface, often in the form of an interactive map or dashboard. Here, users can track the location and movement history of individual objects in real time.

Modern RTLS solutions, such as the Realtime Asset Visibility Hub from SmartMakers, not only enable pure location recording, but also analyses and reports as well as the automation of processes. For example, the system can automatically post material movements to ERP systems or issue warnings if an object reaches a certain zone or remains stationary for too long (geofencing).

What should you look out for when choosing an RTLS?

As production processes and warehouse logistics differ greatly depending on the industry and company, the RTLS should be tailored to your specific requirements. A few key points that you should consider when making your selection are

- Positioning accuracy and update rate: Depending on the production process, the material flow and the asset to be tracked, there are different requirements for positioning accuracy and update rate. Some processes require centimetre-precise positioning and millisecond-precise updating, while for others it is sufficient to determine the location of a component with an accuracy of 2-5 meters at a frequency of 10 minutes. This requirement has a significant influence on the choice of the right RTLS.

- Compatibility and integration: An RTLS should fit seamlessly into your existing ERP (Enterprise Resource Planning) or MES (Manufacturing Execution Systems) systems to enable a holistic view of all processes. Integration into these systems enables you to incorporate location data directly into production control, make data-based decisions in real time and exploit high automation potential.

- Scalability: The RTLS should be able to grow with your company. A scalable system can be extended to different assets or application scenarios without the need for major technical changes - an essential feature for companies that focus on growth and flexibility.

- Costs and cost-effectiveness: RTLS solutions vary greatly in price and should be in proportion to the expected benefits. This does not always mean that the cheapest or most expensive solution is the best choice - rather, you should carefully weigh up the investment and the added value of the system in relation to each other.

- Reliability and robustness: Production environments can be demanding, especially due to temperatures, dust or moisture. In addition, a lot of metal is often installed or stored, which can block or reflect signals. The RTLS should therefore work reliably even under adverse conditions in order to continuously provide precise location data. At the same time, the battery life of the devices used should be as long as possible in order to keep maintenance costs to a minimum.

The advantages of the SmartMakers RTLS

The IoT-based RTLS (IoT = Internet of Things) from SmartMakers uses Bluetooth technology and its own mesh architecture, which is specially optimized for IoT applications. It offers you specific advantages in production compared to other technical approaches to location determination. Here are the key aspects in detail:

Real-time localization and data availability

IoT-RTLS-based systems process and transmit location data across all areas in all production halls to central platforms in real time, giving you instant insights into material flow, production utilization and the location of resources. Other systems, such as purely passive tracking solutions, require manual intervention for scanning (barcode or QR code) or stationary readers (RFID) and do not provide continuous location monitoring.

Very low implementation and infrastructure costs

IoT-RTLS solutions require no complex cabling and minimal physical network infrastructure. The hardware is battery-powered and transmits data via its own wireless network, so no LAN connections are required. Installation is therefore very quick and cost-effective. The function of RFID systems, on the other hand, is based on the installation of readers at all points where information is to be recorded. A UWB system requires a close-meshed network of gateways that require power and network connections for precise localization. Both are therefore significantly more expensive and less flexible to set up and operate. Installation costs and effort for the SmartMakers RTLS system are 7 to 10 times cheaper.

Flexibility and scalability

IoT-based RTLS systems can be easily adapted and expanded to suit changing production environments. They grow with the requirements of your company. Systems that require a larger infrastructure are less flexible as they have to be physically modified and cannot be expanded dynamically. The SmartMakers RTLS has decentralized network management, where each device makes its own decisions about data forwarding. This means that no central network controller is required, which further increases scalability and reliability.

Sustainability and energy efficiency

Modern IoT-RTLS systems work with energy-efficient radio technologies and offer long battery life. This lowers operating costs and reduces environmental impact. Other approaches, such as UWB, are often more energy intensive and have a shorter lifespan, requiring regular maintenance.

An RTLS that offers production companies a high ROI and pays for itself quickly

The RTLS system from SmartMakers has been specially developed for production companies that require a cost-effective solution that is quick and easy to implement. Seamless integration into existing infrastructures and ERP systems allows you to optimize your production processes immediately without complicated conversions.

The SmartMakers RTLS uses the latest IoT-based tracking technologies, which not only provide precise location data, but also impress with their high automation potential. You benefit in particular from the increased transparency and detailed real-time analyses, which help to reduce costs, minimize throughput times and continuously streamline processes.

The RTLS solution is offered as a managed service that includes all the components required for smooth operation. Customers of SmartMakers therefore do not need to build up their own in-house expertise. Especially in times of a high shortage of skilled workers, production companies can quickly exploit the great potential of an RTLS and benefit from SmartMakers 's wealth of experience.

Would you also like to benefit from the advantages of real-time localization in your production? We will be happy to advise you free of charge and without obligation!