In this article, we will show you the various applications of IoT inventory management. We go into detail about how IoT can significantly improve the accuracy and efficiency of tracking, analyzing and managing inventory.

Introduction to IoT Inventory management

By implementing IoT in inventory management, companies are experiencing a turning point that fundamentally changes the traditional approach to inventory management. The introduction of IoT technologies enables a significant increase in accuracy, efficiency and transparency, revolutionizing previously manual and error-prone processes. We begin by explaining the underlying concept before moving on to specific application examples and concluding by summarizing the key findings.

The concept of IoT in inventory management

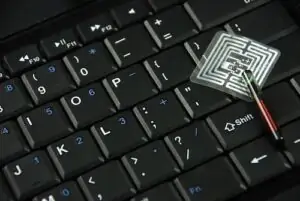

The concept of IoT in inventory management involves the use of networked devices and sensors to monitor, manage and optimize inventories. It creates a seamless connection between physical products and digital information systems. The core aspect of IoT in inventory management is the ability to capture and analyze data in real time using sensors, RFID and other IoT devices. This leads to a significant increase in efficiency in warehouse management.

Inventory management with IoT: the applications

Below we take a closer look at the following applications for inventory management with IoT :

- Real-time tracking and visibility

- Monitoring

- Data accuracy and analysis

- Rationalization

- Integration into the supply chain

- Maintenance and inventory planning

- Customer satisfaction

- Challenges

Real-time tracking and visibility through IoT inventory tracking

IoT-based inventory tracking enables real-time tracking of inventory, which represents a significant step forward. Thanks to technologies such as RFID (Radio-Frequency Identification), GPS and various sensors, companies can now track the precise location and status of their stock in real time. Contactless data collection using RFID tags on products or pallets ensures fast and accurate inventory tracking. GPS transmitters are used in transportation in particular to track goods over long distances. In addition, sensors, especially in the food industry, provide information on temperature and humidity to monitor the condition of products. This not only leads to an increase in accuracy, but also to increased transparency along the entire supply chain.

Automated monitoring of stock levels

The integration of the Internet of Things plays a key role in the automation of warehouse inventory monitoring. Inventory data is continuously recorded and analyzed using IoT devices such as sensors and radio tags. These systems are able to automatically detect when certain inventory thresholds are reached - be it critically low stock or excess stock. Intelligent shelves can be equipped with weight sensors, for example, which detect changes in the weight of the stock and automatically trigger a reorder or send warning messages if necessary. In addition, IoT devices are ideal for analyzing consumption patterns and predictive stock adjustment, and can be linked to integrated analysis tools. This leads to more efficient inventory management, a reduction in supply bottlenecks and a minimization of excess stock.

Increased data accuracy and analysis

By using IoT devices with sensors, RFID tags and intelligent scanners, data is recorded directly and automatically in the system. This leads to a reduction in manual input errors and an improvement in data quality. The use of IoT will be indispensable in the future to avoid stock shortages and ensure efficient inventory management. In addition, IoT plays a central role in providing detailed insights and analysis to optimize inventory levels. Companies can identify consumption patterns and trends, leading to more accurate forecasting of stock requirements. These analyses through IoT-based inventory management enable entrepreneurs to better respond to market changes, increase customer satisfaction and create more accurate demand forecasts.

Rationalization of warehouse operations

The integration of IoT technologies enables precise data collection on warehouse movements and usage, resulting in more effective planning of warehouse operations. These technologies enable the optimization of warehouse routes, more efficient placement of items and minimization of stock levels. In addition, IoT facilitates organization and automation by means of driverless transport vehicles, which are able to move goods quickly and efficiently between different locations. They not only help to increase operational efficiency, but also improve the working environment for employees through ergonomic design options, for example when storing, sorting or packing products.

Integration with supply chain management

The integration of IoT enables a comprehensive overview and effective coordination of the entire supply chain. Through IoT solutions, suppliers, warehouses, distribution centers and responsible professionals are seamlessly connected. This improved transparency between all parties involved in the supply chain promotes collaboration. For example, companies can plan delivery times more precisely, react more flexibly to fluctuations in demand and avoid delays or breakdowns.

Predictive maintenance and inventory planning through IoT based inventory management

The use of IoT in inventory management also simplifies predictive maintenance. Sensors can monitor the condition of warehouse equipment such as conveyor belts, vehicles and racking systems. Based on this data, maintenance requirements can be identified at an early stage. In the area of inventory planning, IoT enables predictive analyses based on patterns and forecasts. This allows demand to be predicted more precisely and stock levels to be adjusted optimally.

IoT Inventory management for an improved customer experience

More precise inventory management using IoT can significantly improve customer satisfaction. Companies are able to respond more quickly to customer requests and process orders more efficiently. Real-time in-store monitoring allows customers to accurately view product availability and receive reliable assurance of fast delivery. Real-time tracking of orders also contributes to higher customer satisfaction, as customers can see the current location of their product at any time.

Mastering challenges in portfolio management using IoT

The introduction of IoT for inventory management poses challenges, particularly in terms of data protection and technical complexity. Data security and protection against hacker attacks must also be taken into account. One solution is to choose IoT platforms that are easy to integrate and scale. Training and continuous education of employees is also crucial to ensure that they can exploit the full potential of the new technology. Best practices to overcome these challenges include thorough risk analysis, compliance with all data protection standards and implementation of cybersecurity measures. It is advisable to test IoT on a small scale first before rolling it out across the organization.

Conclusion on IoT for inventory management

The introduction of IoT in inventory management will have a transformative impact on business practices in the future. By integrating this technology, organizations can achieve unprecedented accuracy and efficiency. The implementation of IoT solutions is a key strategy to strengthen the competitiveness of companies. Now is therefore the right time to set the course for this development.