Do you sometimes feel that your company could work even more efficiently? This is where RFID systems for manufacturing can help. These systems make tracking and managing inventory and production processes easier than ever before. Below are six ways RFID systems are revolutionizing processes in industry.

RFID - the future of inventory tracking

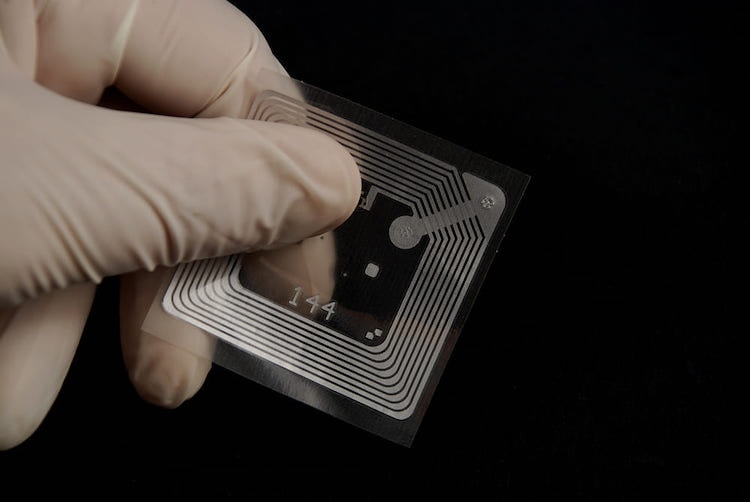

RFID (Radio Frequency Identification) is a technology that uses radio waves to identify and track objects. RFID in manufacturing can be used to track inventory, monitor the production process, and track assets.

RFID - A complete overview

RFID in the manufacturing industry has been used for over two decades and is constantly evolving to meet the ever-changing needs of manufacturers.

RFID tags are typically attached to products or packaging and can contain a variety of information such as product ID, date of manufacture, expiration date and more. This information can be read by an RFID reader, which then sends the data to a computer for processing.

What are the advantages of RFID in manufacturing?

RFID solutions offer a number of benefits to manufacturers, including improved efficiency and accuracy, reduced theft and loss, and better inventory tracking.

RFID systems for manufacturing accelerate the production process.

RFID tracking systems use tags to track the path of products through the manufacturing process. This information is then used to speed up the production process by identifying bottlenecks and inefficient areas. RFID tracking systems have already been shown to reduce production times by up to 30%.

RFID system reduce errors in the production process.

RFID systems are used in a variety of industries to track items throughout the production process. By reducing errors and providing insight into potential bottlenecks, RFID systems can help improve efficiency and quality control.

In many cases, RFID tags are attached to products or components as they go through the manufacturing process. By tracking the location of each tag, the system can provide real-time information about the status of each item.

This information can be used to make adjustments to the production line as needed to prevent errors and optimize performance. Consequently, RFID systems play an important role in improving the quality and efficiency of manufacturing processes.

RFID solutions for manufacturing improve inventory management.

RFID tracking systems for manufacturing are becoming increasingly popular because they offer a number of advantages over traditional methods of inventory management. RFID tags can be attached to products or components, and the data they contain can be read by RFID readers.

This allows manufacturers to track the location of products and components throughout the production process, which can significantly increase efficiency. In addition, RFID tags are resistant to damage and wear, so they can continue to provide accurate data even after years of use. Therefore, RFID solutions offer a reliable and cost-effective way to improve inventory management in manufacturing environments.

RFID systems improve the efficiency of production equipment and extend equipment life.

RFID tags provide a unique identifier for each piece of equipment, making it easier to track inventory and locate lost or stolen items. RFID systems can also help improve the efficiency of production facilities by reducing the need for manual data entry. In addition, RFID tags are often more durable than barcodes, meaning they can extend the life of equipment by reducing wear and tear.

As RFID technology continues to evolve in manufacturing, it is likely that even more manufacturing facilities will adopt RFID systems to improve efficiency and extend the life of their equipment.

RFID systems improve quality control in the manufacturing industry.

RFID systems are becoming increasingly popular in the manufacturing industry. Labels are attached to products and then read by RFID scanners. This allows manufacturers to track products throughout the production process and ensure that each product is accounted for.

RFID systems improve quality control by reducing the risk of errors and increasing efficiency. For example, if a product is mislabeled, the RFID system can detect and correct the error. In addition, RFID systems allow manufacturers to track inventory and quickly replenish items that are running low.

Consequently, RFID systems offer a number of benefits for manufacturers looking to improve their quality control.

RFID systems ensure greater safety and help prevent accidents.

RFID systems are designed to provide greater security and prevent accidents. RFID tags are attached to objects or people, and the system uses RFID readers to track the tags. This information is then used to identify the location of the objects or people. RFID systems are used in a variety of environments, including warehouses, hospitals, and office buildings.

The benefits of RFID systems include improved safety and better asset management. RFID systems can help prevent accidents by providing real-time information about the location of people and objects.

In addition, RFID systems can be used to track inventory so that supplies can be easily ordered when needed. RFID systems therefore offer many benefits and can help improve security in a wide range of areas.

Conclusion RFID systems

RFID (Radio Frequency Identification) systems are becoming increasingly popular in manufacturing. Because RFID tags do not require line-of-sight to be read, they can be used to track items even when they are not visible.

This makes them particularly suitable for inventory tracking in warehouses and factories. RFID tags can also store a larger amount of data than barcodes, making them more versatile and efficient. Implementing an RFID system can be a costly investment, but the benefits usually outweigh the costs.

RFID not only improves inventory management, but can also lead to higher customer satisfaction and profits. As production environments become more complex, RFID is likely to play an increasingly important role.