In this article, you will learn how IoT-based inventory reduction strategies can significantly improve the efficiency and profitability of companies in 2024. This is achieved by reducing excess inventory and ensuring timely availability of products in the warehouse. Read more about how to reduce inventory.

Introduction: How to reduce stocks

Inventory management is a critical success factor in modern business. It significantly influences the cost structure, liquidity and the ability of a company to respond to customer needs.

Inefficiency and excess stock not only tie up capital unnecessarily, but also lead to increased storage and administration costs. In addition, a company's market position deteriorates due to slower response times

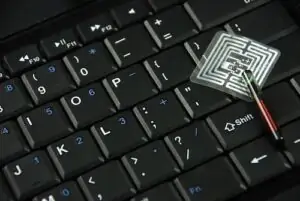

With the advent of the Internet of Things (IoT), new opportunities for optimizing inventory management are opening up. IoT Internet-enabled strategies enable precise control and management of stock levels in real time.

By networking sensors and devices and integrating them into inventory management systems, companies can significantly reduce their stock levels and increase their efficiency. This leads to improved capital utilization, cost savings and increased customer satisfaction.

Financial and operational benefits of efficient inventory tracking

Efficient inventory management is a key aspect of a company's performance and financial health. Through the strategic use of inventory management systems, excess stock can be reduced. This reduces the amount of capital tied up. The freed-up capital can contribute to investments or improved liquidity.

Storage costs are also minimized if throughput times are improved. Of course, this also pleases customers and is reflected in increased customer satisfaction. Optimized inventory management ensures better planning in production and the supply chain. This also increases the efficiency of operational processes.

5 important IoT-based strategies for reducing inventories in 2024

IoT refers to the networking of physical objects with the internet. These have sensors, software and other technologies to collect and transmit data from the environment. In a company, these objects can range from simple devices to complex industrial plants. Through IoT , devices can communicate with each other in real time, enabling efficiency gains, economic benefits and a reduction in human intervention.

One of the main advantages of IoT is the ability to collect large amounts of data, analyze it, take action and use resources more effectively. The challenges of introducing IoT technologies include data protection and ensuring security. Since every device is connected to the Internet, the security concept must be sophisticated. An IT security expert should therefore also accompany the introduction.

With the following IoT-supported strategies, companies can drive forward their inventory reduction more efficiently. By implementing these strategies early on, a clear competitive advantage can be achieved in many sectors. It also lays the foundation for an increasingly networked and data-driven economy in the future.

1. demand forecasting and predictive analytics

Predictive analysis is the analysis of current and historical data in order to make predictions. Predictive analytics combines techniques from statistics, mathematics and machine learning. By connecting IoT devices with predictive analysis tools, companies can collect and evaluate data in real time.

This information makes it possible to predict future trends and fluctuations in demand. As a result, stocks can be planned more accurately and unnecessary warehousing can be avoided. This saves significant costs for the company.

2. automated reordering systems

The IoT inventory tracking system also enables the ordering process to be automated. This means that sensors can continuously monitor stock levels and automatically trigger repeat orders if the minimum order quantity is not reached. This reduces the risk of shortages and makes the ordering process more efficient. With outdated solutions, it often happens that goods are not reordered in time.

This is not only detrimental to sales, but also annoys customers. Experience shows that customers prefer to order from the competition if the identical product is in stock there. Hardly any customer will tolerate a waiting time of more than a week.

3. dynamic inventory optimization

By using software, the IoT inventory can be optimized in real time. This allows companies to react much more flexibly to market changes. The system adapts stock levels to actual demand.

Companies that are heavily affected by seasonal events are a clear example of the benefits of this function. For example, the demand for gift items on Father's Day, Mother's Day, Christmas or Easter will be higher than the rest of the year. Intelligent systems automatically adjust this demand in the warehouse.

4. improved supplier cooperation

Closer collaboration with suppliers involving IoT can lead to a seamless flow of information. The shared data means that delivery cycles can be better tailored to the respective requirements. But not only that, delivery times will also be considerably shorter. As a result, the company's warehousing costs will be reduced and the ability to respond to customer requests will increase. This also minimizes misunderstandings caused by the passing on of incorrect data.

Another factor that should not be underestimated is the improved communication between the supplier and the company. Smooth cooperation is ultimately also a guarantee for long-term supplier loyalty.

5. inventory analysis and reporting

Intelligent analysis tools that use IoT data enable companies to gain deeper insights into the inventory situation. By analysing the data, strategic decisions can be made on inventory optimization. The possibilities for analyzing data are almost unlimited compared to a few years ago. With the right software, all the desired data can be clearly presented. This point also leads to lower costs for the company.

Summary: Reduce inventory through IoT

IoT has become a fundamental component of modern inventory management systems. In 2024, we can expect IoT technologies to play an even more central role. The networking of devices and sensors enables unprecedented transparency and control over stock levels in real time. This allows companies to automate processes, create precise demand forecasts and dynamically optimize stock levels. All of this leads to a significant reduction in excess stock and costs.

Companies that are able to implement IoT strategies are currently positioning themselves for a significant competitive advantage. The implementation of IoT solutions makes it possible to react agilely to market changes. Customer satisfaction also increases as delivery times become shorter.

If you are a decision maker in your company, then you should recognize the enormous potential of IoT methods to reduce inventory. The time to act is now to set the course for a successful future. Benefit from lean, responsive and data-driven inventory management with IoT.